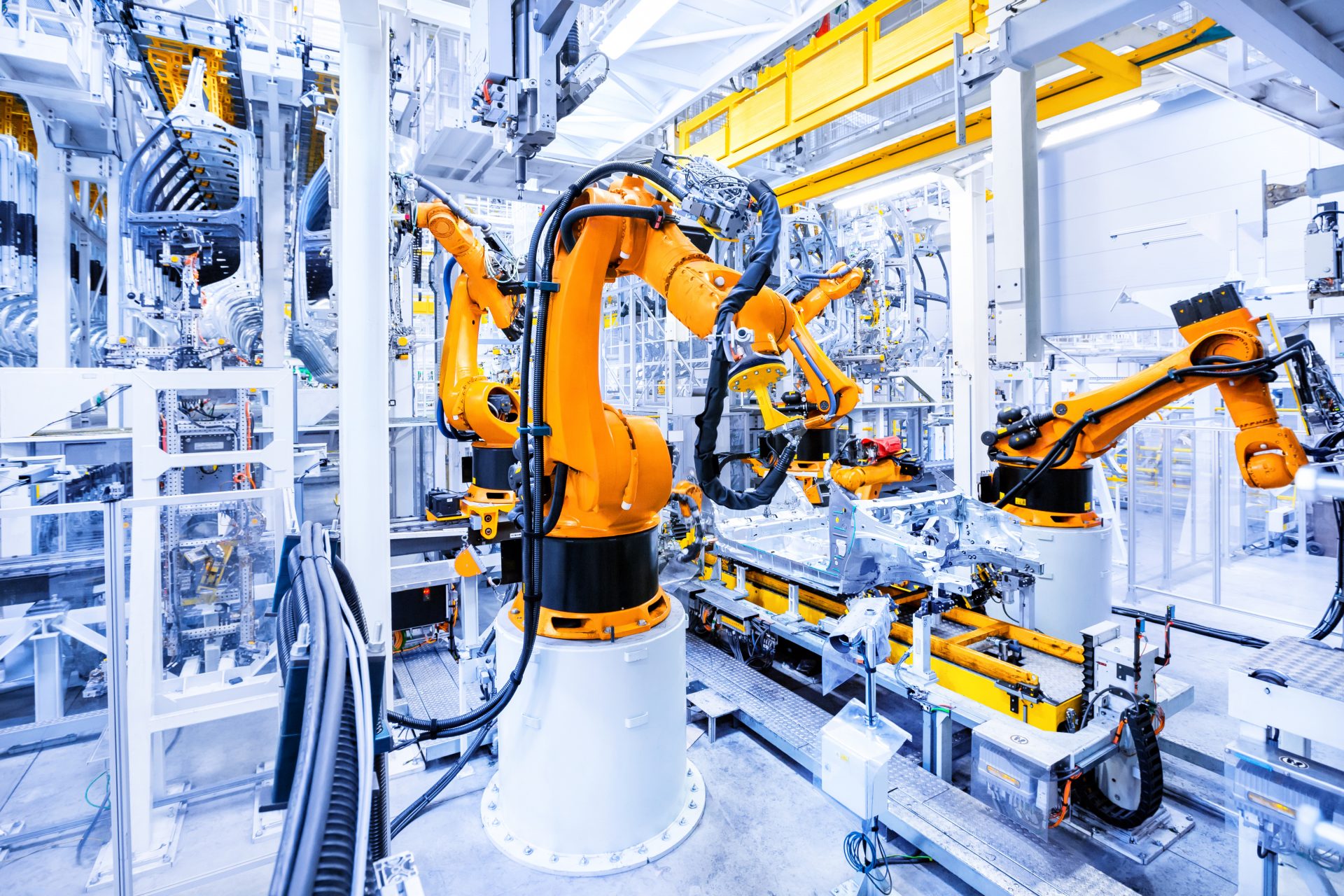

The world is seeing a rapid advancement in deployment and automation of machines, ranging from robotics to energy conversion system, manufacturing systems and heavy machinery. Real-time sensor information is highly available as well as increasing computational power in such systems, both of which are yet to be fully exploited. Together with our customers we have developed solutions to shift from making an industrial system simply operate, to optimizing its performance potential by deploying and fully utilizing the power of real-time numerical optimization technology. By providing our expertise in control-oriented modelling, optimization problem formulation and efficient hardware implementation we have achieved significant improvements in safety, productivity, and energy efficiency of automated industrial machines. A few of the applications we have worked on are described in the list below.

REAL-TIME Robotic Motion Planning

Robots are used more and more in dynamic environments. As a result, a static, pre-computed motion planning is not sufficient any more. Instead, the motion plan needs to be recomputed in real-time to account for the changing environment. Besides offering the specific product PROBOT for this problem, we work together with partners and end-users to develop tailored solutions for industry-relevant applications. In both cases FORCESPRO is used as the basis technology to address the arising challenges. The solutions offered can be embedded on any hardware-platform and are quick to market. Have a look at the example of collaborative bin-picking.

ADvanced Control of CNC Machines

The requirements on CNC machines are constantly increasing in terms of speed of production and cost-effectiveness. To advance the process behavior, the hardware as well as the software are continuously improved. We have worked successfully together with customers on the design of optimization-based solutions for CNC machines. For this purpose, our product PROBOT was integrated in the customer’s CADCAM system and on real-time embedded hardware. As PROBOT is based on the technology of FORCESPRO, the optimization problems can be solved reliably and very fast. This allows application for motion planning as well as advanced control problems. The solutions developed allowed to improve the speed of production while maintaining the quality of the produced parts. Have a look at the example of motion planning for CNC machines.

INNOVATIVE WIND TURBINE CONTROL

PROBLEM

Wind turbine control systems are essential to maximize power extraction from the wind while minimizing structural loads. The control system consists of various parts, such as the yaw controller, responsible for aligning the wind turbine with the wind direction, and a production controller, responsible for setting the desired pitch angle of the blades and the desired power output from the electrical converter. At the same time modes for low wind speed and high wind speed need to be taken care of.

SOLUTION

The challenges associated with wind turbine control systems can be overcome with a model predictive control (MPC) algorithm using FORCESPRO. The holistic MPC approach with a physics-based model eliminates the switching between different modes and can deliver high performance for all operating conditions. The model-based design approach significantly lowers the number of tuning parameters, and exposes in an intuitive manner the trade-offs between power output and structural loads that are inherent to any turbine design.

RESULTS

MPC controllers generated with FORCESPRO were embedded in wind turbine control software and deployed to turbines in the field where they are operating flawlessly for years. Compared to the traditional control system, they can reduce the mechanical loads, while at least the same amount of energy is extracted from the wind. Due to its physics-based nature, the approach can be easily transferred to other wind turbines. This is especially advantageous, as manufacturers offer various modularized configurations of wind turbines.

Looking for more information?

If you'd like to find out more about our Logistics Solutions, let us know. Either use the webform on the right or book a meeting via the link below. Our team of experts will be happy to discuss more details with you.